Quote:

Originally Posted by RJVB

Torrefied tops smell of coffee, baked ones of pastry and then there may be ones that would smell of bourbon if only you could make them out of white oak?

Almost: https://en.wikipedia.org/wiki/Torrefaction#Process

Putting wood that isn't 100% dry in a vacuum could well destroy it; have you ever seen what a cup of water does when you put it in a vacuum chamber and activate the thing? |

Keep watching that cup.

"One key advantage to vacuum drying is reduced drying time. The drying time in a vacuum kiln is significantly less than in a conventional steam kiln. For example, a recent study found that a 1-in.-thick hard maple charge was dried in a vacuum kiln in 2 days (58 hours), whereas a paired 1-in.-thick hard maple charge was dried in a conventional steam kiln in 12 days (288 hours) (Lyon and others 2021). This advantage is even more pronounced with thick stock, such as large table slabs or mantle pieces."

https://www.fpl.fs.usda.gov/documnts...fpl_gtr287.pdf

Quote:

Originally Posted by fazool

So my understanding is that the process goes like this:

draw a vacuum under temperature, removing moisture from the wood

backfill with nitrogen and bake

pressuring with high humidity to re-inject moisture back into the wood

|

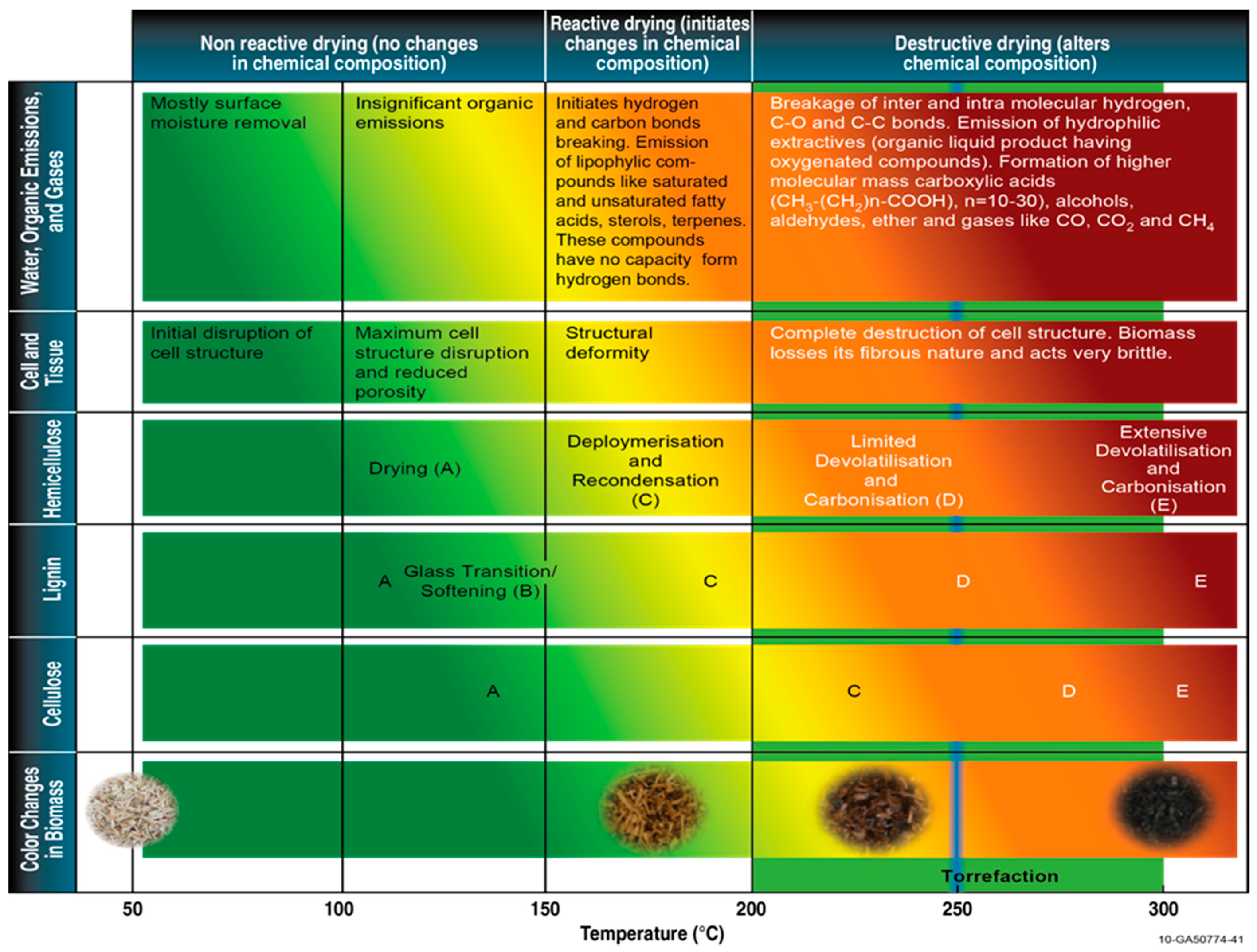

Time to update your understanding. If you want to create fuel then high temperature torrefaction is your thing. If you want to make instrument wood a lower temperature would be better. The process is slower but it can be done at a temperature below the ignition point of wood. The catch, good temperature control and uniformity throughout the oven. The bulk of the wood done for guitars are done this way (just saying most as I do not know if Yamaha is still doing their tops themselves). I can not find the graph I saw years ago on the elements that decompose compared to temperature. Found this though.

Most of the charts have torrefaction starting at 200 C, nice of Nature to round off to a nice even number. But when you are doing biomass you do not want to go 30 mph when you can go 60. Oh, I just remembered, Taylor does their own. Wood going into a standard industrial oven, wood implode if a vacuum was pulled. They could just purge with nitrogen but there is no point as this oven would have no problem doing a load in two hours at a temperature below where the wood ignites. As an aside, I have torrified wood in air, have worked on heating equipment like the oven in the video.

https://youtu.be/cv3cM0qQecY?t=75

On baking compared to torrified, the backed tops would have any pitch solidified, no changes to the wood otherwise. The Adkin video has them baking at 90 C. I have gone up to 120 C to bake tops.